|

|||

Race car performance |

|||

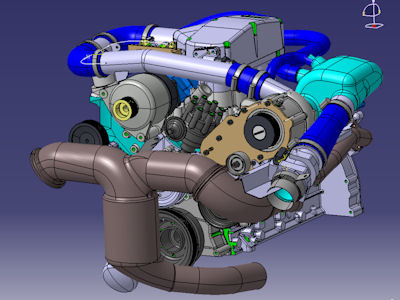

SC Power supercharger systems transform your car to Supercar performance, the power of the SC450/SC500 being comparative to cars running in the Tuscan Challenge race series, that’s quick. The 4.0 litre engine is a very responsive and free revving unit making it a pleasure to drive. The SC400 system retains this quality and with around 300+bhp available delivers superior drive-ability and performance to 5.0 litre engines. Customers who later fitted the intercooler system with an aftermarket ECU have achieved 385BHP, not bad for a stock engined 4.0L!!! The change to 4.0 litre performance is quite astounding and is very noticeable when accelerating in 4th and 5th gear through the 100mph barrier. It just keeps going. |

|||

SC Supercharger Systems increase engine horsepower and torque by approximately 40% generating an additional 80+bhp of power. |

|||

Easy Installation |

|

||

Each SC system is supplied with a very comprehensive installation manual providing step by step instructions together with comprehensive diagrams and drawings to assist the build If you are handy with a spanner you can fit the SC systems. Time taken by our customers when working in the evenings is around 15-20 hours. All comment when finished how satisfying it was to build their own installation, fire the engine up and to drive it for the first time. The SC systems are supplied with all parts to complete the build, with the exception of minor wiring revisions to the existing electrical harness and the EPROM chip, if required. |

|||

|

Is your car suitable? |

||

|

The SC systems are specified to the standard engine build. Maximum hp is contained within the limitations of the engine or driveline of each model variant. |

||

|

|||

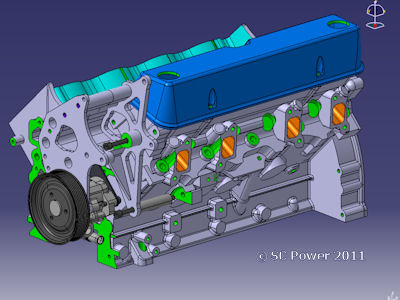

Engine and driveline |

|||

Engines should be in good fettle and without excessive wear. If unsure of the engine condition, we advise that cylinder leak down and compression tests are carried out, as well as a camshaft check. This can be simply carried out by measuring the valve/pushrod movement to ensure the cam shaft lobes are uniform and not worn excessively. For customers wanting more power, and there are some, the performance of the SC system can be specified against their engine build to ensure optimal and maximum performance. The standard cooling system works exceptionally well , there is no need to change the radiator or revise the cooling system. |

|||

Brakes and suspension |

|||

SC systems do not increase vehicle top speed, only performance throughout the engine rev range. Power delivery is very smooth, without surge and ensures the chassis and suspension and driver are not overstressed. |

|||

|

|||

SC Power design objective: To produce more Hp/ton than a Porsche GT3 |

|||

Approximate Supercharged Hp Assuming 15% trans. loss |

|||

Flywheel HP |

Weight in KG |

Power/Weight ratio |

|

Porsche GT3 |

415 |

1395 |

297 HP per tonne |

SC400 |

312 |

1065 |

292 HP per tonne |

SC450 |

341 |

1065 |

320 HP per tonne |

SC500 |

365 |

1065 |

343 HP per tonne |

Performance that speaks for itself |

|||

System cost from £39/hp increase. Compare this to any other conversion

Rear wheels, Actual Dyno results @ 15% drive-line loss |

Flywheel Calculated |

|---|---|

SC 400 265 Bhp 280 Ft/lbs Click for Power Graph |

310 Bhp 329 Ft/lbs |

SC 450 290 Bhp 304 Ft/lbs Click for Power Graph |

340 Bhp 357 Ft/lbs |

SC 500 316 Bhp 330 Ft/lbs Click for Power Graph |

370 Bhp 388 Ft/lbs |

Reference: Normally aspirated engine outputs |

Flywheel Calculated |

400 (NA) 180 Bhp 200 Ft/lbs |

212 Bhp 235 Ft/lbs |

450 (NA) 211 Bhp 241 Ft/lbs |

248 Bhp 283 Ft/lbs |

500 (NA) 221 Bhp 271 Ft/lbs |

260 Bhp 319 Ft/lbs |

Drive line power losses between the engine flywheel and the rear wheels vary dependant upon in which gear the dynamometer test is carried out, the condition of the vehicle drive line, atmospherics and tolerance of the rolling road.

Typical quoted power losses vary between 15 and 22%, for this reason TVR Power state the achieved Bhp and Torque at the rear wheels and quote flywheel horsepower based upon the minimum losses of 15%, in effect the lowest realistic output. SC 400 delivers stunning performance superior to its naturally aspirated TVR 500HC stable mate.

The drive-ability of the car is excellent, with the system returning good fuel consumption better than the 5.0 litre. Driving the Supercharged cars is an unbelievable experience; members of TVRCC will have read in TVR Sprint the excellent reviews of the car and installation.

The SC450 delivers greater performance as demonstrated by the performance graph than the SC400, whilst retaining the excellent drive-ability for which the SC cars are becoming known. SC500 achieves superlative performance equal to the dunlop challenge race car, ensuring a huge constant grin when watching fellow tivers shrink in the rear view mirror, the SC500 delivering 340hp per ton with driver. What do you get?

| Parts Listing | SC400 Chim |

SC450 Chim |

SC500 Chim |

SC500 Griff |

Installation manual |

X |

X |

X |

X |

Rotrex supercharger |

X |

x |

||

Larger Rotrex supercharger |

X |

X |

||

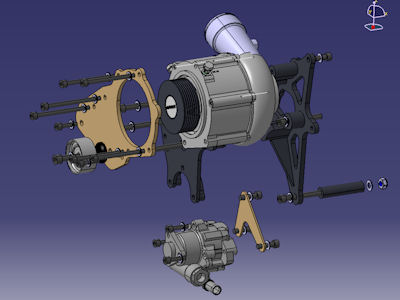

Supercharger mounting system with polished alloy face plate |

X |

X |

X |

X |

Supercharger oil, reservoir, oil cooler and hoses |

X |

X |

X |

X |

High quality SC drive belt |

X |

X |

X |

X |

Secondary supercharger plenum |

X |

X |

X |

X |

Polished aluminium crossover induction pipe |

X |

|||

Aluminium intercooler with polished aluminium induction pipes |

X |

X |

X |

|

Mounting system for intercooler and oil cooler |

X |

|||

Twin K&N ail filter system with polished alloy pipes |

X |

|||

Induction silicone pipes |

X |

X |

X |

X |

Silicone vacuum pipes |

X |

X |

X |

X |

Re-circulatory air pressure relief valve |

X |

X |

X |

X |

Re-circulatory silicone air return pipe |

X |

X |

X |

X |

Adjustable fuel regulator |

X |

X |

||

Fuel injectors with increased flow rate |

X |

X |

||

Mounting bracket for coil/coil packs and SC oil reservoir |

X |

X |

X |

X |

One way air valve for trumpet base |

X |

X |

X |

X |

Aluminium sealing plugs for plenum |

X |

X |

X |

X |

All fixings and S/S jubilee clips |

X |

X |

X |

X |

Polished aluminium mounting plate for air flow meter |

X |

X |

X |

X |

|

||||

Options |

||||

Engine oil breather catch tank |

X |

X |

X |

X |

EPROM chip for 14CUX |

X |

X |

X |

X |

Power steering mounting system with hydraulic hoses |

X |

X |

X |

X |

K&N High flow air filter |

x |

x |

x |

SC Power Ltd Supercharger assembly

Induction system

Performance enhancing secondary air plenum, intake tube from air flow meter to Secondary plenum, cross tube and hoses from Supercharger to primary plenum, air pressure release valve, bypass hoses and hose clamps for each union.

Cooling

Heat shield between the exhaust and Supercharger (LH), heat shield between the exhaust and plenum intake (RH), coolant top hose and modified engine coolant Swirl Pot.

Engine related parts

Hi performance fuel regulator with supply and feed hoses, mounting bracket for SC Oil reservoir and Coil components, mounting bracket for hi performance fuel regulator if fitted, power steering hoses, vacuum hose for system operation and blanking plug to seal plenum.

Available options:

Polished Supercharger faceplate and air cross tube to improve appearance (Anodised standard finish), polished finish to Swirl pot and Coolant expansion tank, Finish of parts as supplied, Uniform loading hi specification hose clamps to improve hose security, conventional SS hose clamps standard fitment, primary plenum spacer incorporating heat sink to improve throttle response and performance.

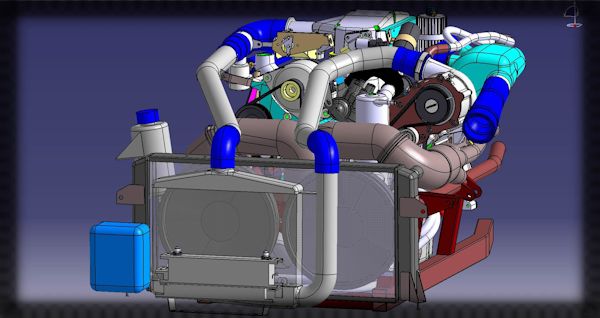

Intercooler

The SC500 IC Package is now complete, the system intake temperatures being reduced, permitting more effective filling of the combustion chambers with further advance of the ignition. The result is quite staggering with a significant increase in performance without loss of throttle response.

This Intercooler is available as part of the SC500 package or as an individual item available as an retrospective upgrade to installed supercharger systems.

The intercooler pipes shown on the picture below right are currently fitted to our development car. All intercooler kits that we sell will come with polished tubes..

|

|

|